I was having trouble moving the carriage on one of the KH 930s yesterday while trying to make lace for the first time since 1994.

So I first checked the carriage, and there was some yarn wrapped around the brushes. Removed it. Decided to replace the brushes with the extras I had purchased for this purpose. When I removed the brushes to replace them, I found additional yarn wrapped in a tight little circle around the spindle. Replaced the brushes. Checked the rotation - one of the brushes would not move easily.

I just knew I had replaced everything just the way I found it, so I was confused. I went into a Zen-like trance of observation and noticed that one of the little wheels (daisy-like piece of plastic) was concave, and the other was convex. I don't remember removing that wheel, but OK, flipped the one on the side where the brush did not move easily, and replaced the brush again. Now the brush is moving easily.

Replaced the carriage on the bed of the machine and observed I was still having trouble moving the carriage when patterning. I once again entered into the trance. I realized that the belt was buckling when I tried to move it manually by inserting a tool into a slot in the belt.

I replaced the carriage and had a moment of panic when I realized the machine did not pattern now. What did I do? I powered off the machine and pulled the plug, waited 5 seconds, and plugged back in. (I had no specific reason to believe this would work, except that sometimes my computer needs this treatment...)

Thinking perhaps there was some issue with the needles, I removed the sponge bar. Pulled every needle to hold position and replaced it. Then replaced the sponge bar. No change.

My husband, who always likes to take things apart and put things back together, suggested that perhaps I needed to remove the cover.

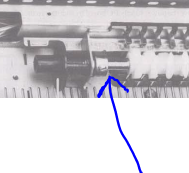

I didn't want to do it, but I wanted the machine to work again, so I did it. First the right side, then realized I would need to remove the left side as well to get an unobstructed view. After both sides were removed there was one more cover that needed to come off in order to see the mechanism. He said that the black plastic encoder wheel was turning fine but the spindle was not. Either a bearing has failed or maybe it just needs lubrication, he said. So I added some of the machine oil at the point below and at the other end.

After replacing and reassembling everything, I worked the carriage back and forth, with much improved operation. The machine is about 30 years old, and that has never needed lubrication until now. I wonder what else needs to be cleaned and lubricated?

Saturday, January 3, 2015

Stash inventory

I decided I would be more productive knitting if I knew where my yarns were and what I had, instead of spending time searching for the right yarn for each project.

I had several plastic bins with coned yarn under the basement stairs. Plastic to keep any unexpected flooding out, and under the stairs to keep the yarn away from light sources to prevent fading. In order to find a particular cone of yarn, I had to move each bin, take the lid off, look inside, and then if the yarn was not in that bin, move the bin again to allow me to look in the next bin. Even though the bins are translucent plastic, I find that I am not always able to determine what is inside by looking through the lid, especially if the lid is covered by another bin.

I found a great shelf unit on Amazon.com - it has the right size between shelves to allow the plastic bins to slide in. Each shelf unit holds 8 bins.

I did not realize until I started this project that, with recent acquisitions, I now had more than 24 bins (some with fabric, not all yarn) until I started stacking the bins on the three shelving units. No wonder I was having trouble finding the yarn I wanted! For the present, I am going to limit myself to 24 bins for yarn. I won't buy any more yarn until I use some of the yarn I already have, to make space.

Fabric will have to be addressed at a later date.

I labeled each bin with a 2-digit code - a letter to indicate which shelving unit, and a number between 1-8 to indicate which spot the bin occupies on the shelving unit.

Next, I started the inventory. The first night I tackled two bins. For each cone of yarn, I take a picture and upload to Ravelry's "stash" tool. Ravelry has fields for yarn colorway and color category, weight, name, manufacturer, date purchased, dye lot, cost, and a field for text entry of comments. Easy, because each bin had about 5 cones. Last night I completed the third bin.

I found some yarn in last night's bin that will be suitable for my final project for TKGA's Knitting Machine Master's program, Level 1. My primary mission is accomplished! But I still want to continue the inventory project.

I think I now can appreciate the acronym STABLE - STash Acccumulation Beyond Life Expectancy.

I had several plastic bins with coned yarn under the basement stairs. Plastic to keep any unexpected flooding out, and under the stairs to keep the yarn away from light sources to prevent fading. In order to find a particular cone of yarn, I had to move each bin, take the lid off, look inside, and then if the yarn was not in that bin, move the bin again to allow me to look in the next bin. Even though the bins are translucent plastic, I find that I am not always able to determine what is inside by looking through the lid, especially if the lid is covered by another bin.

I found a great shelf unit on Amazon.com - it has the right size between shelves to allow the plastic bins to slide in. Each shelf unit holds 8 bins.

I did not realize until I started this project that, with recent acquisitions, I now had more than 24 bins (some with fabric, not all yarn) until I started stacking the bins on the three shelving units. No wonder I was having trouble finding the yarn I wanted! For the present, I am going to limit myself to 24 bins for yarn. I won't buy any more yarn until I use some of the yarn I already have, to make space.

Fabric will have to be addressed at a later date.

I labeled each bin with a 2-digit code - a letter to indicate which shelving unit, and a number between 1-8 to indicate which spot the bin occupies on the shelving unit.

Next, I started the inventory. The first night I tackled two bins. For each cone of yarn, I take a picture and upload to Ravelry's "stash" tool. Ravelry has fields for yarn colorway and color category, weight, name, manufacturer, date purchased, dye lot, cost, and a field for text entry of comments. Easy, because each bin had about 5 cones. Last night I completed the third bin.

I found some yarn in last night's bin that will be suitable for my final project for TKGA's Knitting Machine Master's program, Level 1. My primary mission is accomplished! But I still want to continue the inventory project.

I think I now can appreciate the acronym STABLE - STash Acccumulation Beyond Life Expectancy.

Subscribe to:

Posts (Atom)